Qaab-dhismeedka Dhismaha PP Hollow Line Line Extrusion

Qaabka Dhismaha PP-banwaa wax soo saarka ilaalinta tamarta iyo cagaarka. Waa badeeco jiil kale oo cusub ka dib qaabka alwaax, qaabka birta la isku daray, alwaax bamboo ah oo dhejis ah iyo dhammaan qaab-dhismeedka birta ee waaweyn. Waxay si buuxda u bedeli kartaa qaabka caadiga ah ee qaabka birta iyo qaabka alwaax, ilaalinta tamarta, ilaalinta deegaanka iyo kharashka amortization hooseeya.

Sideed faa'iido

1. Si siman oo siman. Qaabka qaabaysan waa in loo kala qaybiyaa si adag oo siman. Burburinta ka dib, dusha sare iyo dhammaadka qaab dhismeedka la taaban karo waa in ay ka badan yihiin shuruudaha farsamada ee qaab-dhismeedka caddaaladda ee jira. Looma baahna dhejinta labaad, taas oo badbaadisa shaqada iyo alaabta.

2. Fudud oo fudud in la xidho. Miisaanka fudud iyo la qabsiga habka adag, waa la jeexan karaa, la qorsheeyey, la daloolin karaa oo la musbaari karaa, wuxuuna samayn karaa joomatari kasta oo la rabo si uu u daboolo baahiyaha qaab dhismeed ee qaabab kala duwan.

3. Burbur fudud. Shubka kuma dhegna dusha sare ee saabka umana baahna wakiilka sii daynta. Way fududahay in la jeexjeexo oo laga saaro dambaska.

4. Deggan oo u adkaysta cimilada. Xoog farsamo sare, ma barar, dildilaaca, qallafsanaan, size deggan, iska caabin alkali, anti-daxalka, olol retardant iyo biyuhu, rat iyo cayayaanka hooseeyo heerkulka - 20 ℃ ilaa + 60 ℃.

5. Ku haboon dayactirka. Qaabka qaabaysan ma nuugo biyaha umana baahna dayactir gaar ah ama kaydin.

6. Kala duwanaansho xooggan. Nooca, qaabka iyo qeexitaanka ayaa loo habeyn karaa iyadoo loo eegayo shuruudaha injineernimada dhismaha.

7. Kharashka yaree. Waqtiyada rogrogiddu waa badan yihiin, qaabka diyaaraddu wax ka yar 30 jeer, iyo qaabka looxa tiirarka aan ka yarayn 40 jeer, oo leh kharash isticmaal hooseeya.

8. Badbaadinta tamarta iyo ilaalinta deegaanka. Dhammaan alaabta hadha iyo qaabka qashinka dib ayaa loo warshadayn karaa.

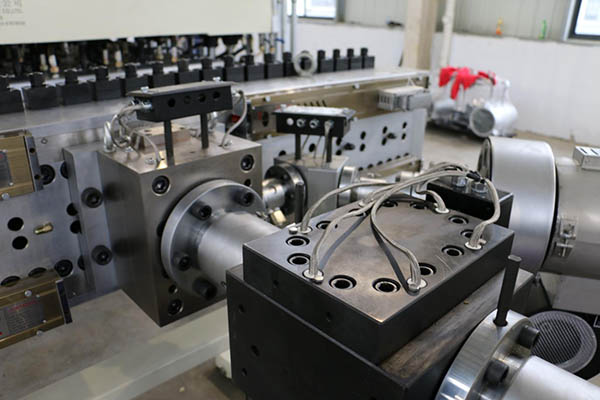

JWELL waxay soo saartay PP hal caaryada labanlaabaya khadka soosaarka qaab-dhismeedka iyadoo lagu saleynayo khadka-soo-saarka caadiga ah ee 915mm, taas oo aan kaliya buuxin karin baahida wax-soo-saarka ballaaran iyo tamar hoose.

Astaamaha

1. Khadka wax soo saarka coextrusion saddex lakab

2. Qaybiyaha saddex lakab oo isku dhafan

3. Caaryada lakabka badan

4. looxa nooca saddex fasalka

5. Cagaf la isku daray

6. Mashiinka goynta dhererka go'an ee tooska ah

Tilmaamaha farsamada ugu weyn

|

Qaabka |

Qalab |

Faahfaahinta Extruder |

Balaadhka alaabta (mm) |

dhumucda (mm) |

Awoodda (kg/saacaddii) |

|

JWS130(80)-1320 |

PP wax laga beddelay |

JWS130/35, JWS80/35 |

915/1220 |

12-14/15-17 |

450-500 |

|

JWS150(80)-2000 |

PP wax laga beddelay |

JWS150/35, JWS80/35 |

915*2 |

12-14/15-17 |

550-600 |

|

CJWH85(80/52)-2000 |

PP wax laga beddelay |

CJWH85, CJWH52/JWS80 |

915*2 |

12-14/15-17 |

600-700 |

Xusuusin: Tilmaamaha waa la beddeli karaa ogeysiis hore la'aanteed.

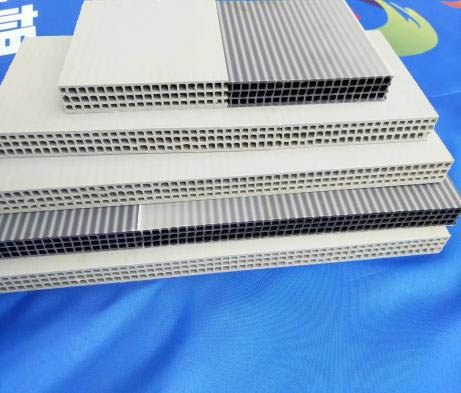

Muujinta sawirka alaabta

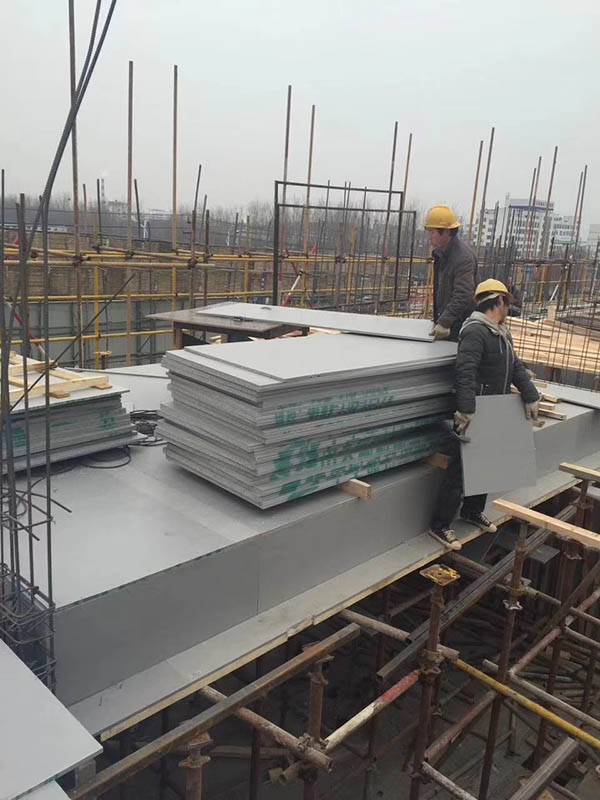

Goobta dhismaha